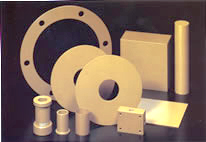

New Polyimide Shape "CEPLA SA101"

CEPLA SA101 is an excellent heat-resistant polyimide shape, based on Biphenyl tetracarboxilic dianhydride(BPDA) originally developed by UBE.CEPLA SA 101 has improved high durability for oxygen plasma, vacuum degassing properties, low water absorption and good processability.Heat distortion temperature is 470ºc, which is higher value than any other organic materials.

[ Feature ]

- Super high heat resistance(heat distortion temperature : 470ºc)

- Excellent plasma resistance

- Low out gas

- Good processability

- Very low impurities

- Low water Absorption

[ Application ]

- Semiconductor production equipment parts

- Vacuum equipment parts

- Precisely processed parts

- Heat and chemical resistant gaskets and sealing materials

General Properties of CEPLA SA101

| Item |

Test Method |

Unit |

Testing Temperature |

Typical value |

| CEPLA SA101 |

Conventional Polyimides a) |

Polybenzimidazol

a) |

| A |

B |

| Tensile Strength |

ASTM D-638 |

MPa |

23 |

110 |

116 |

72 |

160 |

| 260 |

47 |

41 |

37 |

-- |

| Elongation |

ASTM D-638 |

% |

23 |

4.0 |

5.0 |

7.5 |

3.0 |

| 260 |

3.0 |

6.0 |

7.5 |

-- |

| Flexural Strength |

ASTM D-790 |

MPa |

23 |

135 |

160 |

83 |

220 |

| 260 |

51 |

59 |

45 |

-- |

| Flexural Modules |

ASTM D-790 |

Gpa |

23 |

7.5 |

4.2 |

2.5 |

6.6 |

| 260 |

3.6 |

2.1 |

1.4 |

-- |

| Izod Impact Strength

(Noched) |

ASTM D-256 |

J/min |

23 |

20 |

77.5 |

44.4 |

-- |

| Rockwell Hardness |

ASTM D-785 |

M Scale |

23 |

115 |

113 |

-- |

-- |

| Specific Gravity |

ASTM D-792 |

-- |

23 |

1.48 |

1.39 |

1.43 |

-- |

| Breakdown Voltage |

ASTM D-149 |

kV/mm |

23 |

22.7 |

18 |

22 |

20.9 |

| Dielectric Constant |

ASTM D-150 |

-- |

23 |

3.70 |

3.59 b) |

3.64 |

3.3 c) |

| Dissipation Factor |

ASTM D-150 |

-- |

23 |

0.0013 |

0.0012 b) |

0.0034 |

0.003 c) |

| Volume Resistivity |

ASTM D-257 |

ΩEcm |

23 |

1.910-16 |

1.810-16 |

810-14 -10-16 |

810-14 |

| Surface Resistivity |

ASTM D-257 |

Ω |

23 |

8.510-16 |

9.410-16 |

10-15-10-16 |

-- |

| Arc Resistance |

ASTM D-257 |

sec |

23 |

135 |

124 |

-- |

186 |

| Coefficient of Linear Thermal Expansion |

ASTM D-495 |

ppm/ºc |

-- |

35 (25-450ºc) |

55.2

(20-250ºc) |

54

(23-300ºc) |

33

(200-300ºc) |

| Thermal Conductivity |

|

Kcal/mEhºc |

23 |

0.35 |

0.34 |

0.35 |

0.35 |

| 10% Weight loss Temp. |

|

ºc |

-- |

623 |

548 |

-- |

-- |

| Heat Distortion Temp. |

ASTM D-648 |

ºc |

-- |

470 |

360 |

360 |

435 |

| Tabar Abrasion Loss |

ASTM D-1044 |

Mg/1000 |

-- |

20 |

14.7 |

-- |

-- |

| Limiting PV Value |

S45C |

Kgf/cmEm/min |

-- |

2160 (0.1m/sec) |

1050

(0.5m/sec) |

-- |

-- |

| Durability for O2 Plasma d) |

Etching Rate |

|

145-150 |

6.6 |

14.6 |

9.2 |

-- |

| Vacuum Degassing |

TDS Analysis |

TorrE/secEcm2 |

200 |

5.510-4 |

1.010-3 |

2.010-3 |

-- |

| 300 |

7.610-4 |

1.710-3 |

3.210-3 |

| Water Absorption |

ASTM D-570 |

%

(23ºcx24h) |

23 |

0.03 |

0.46

(23ºc48h) |

0.24 |

0.4 |

|